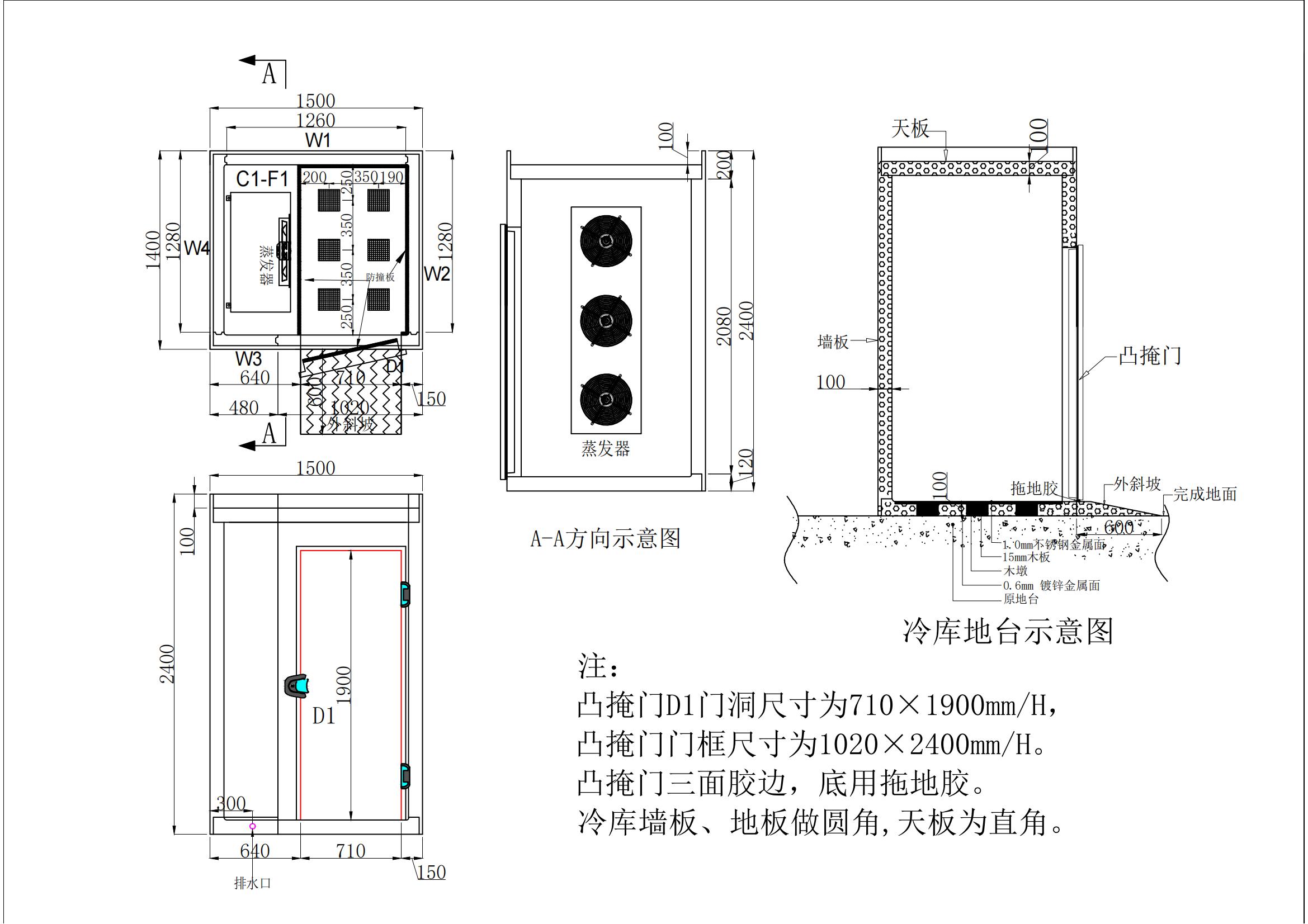

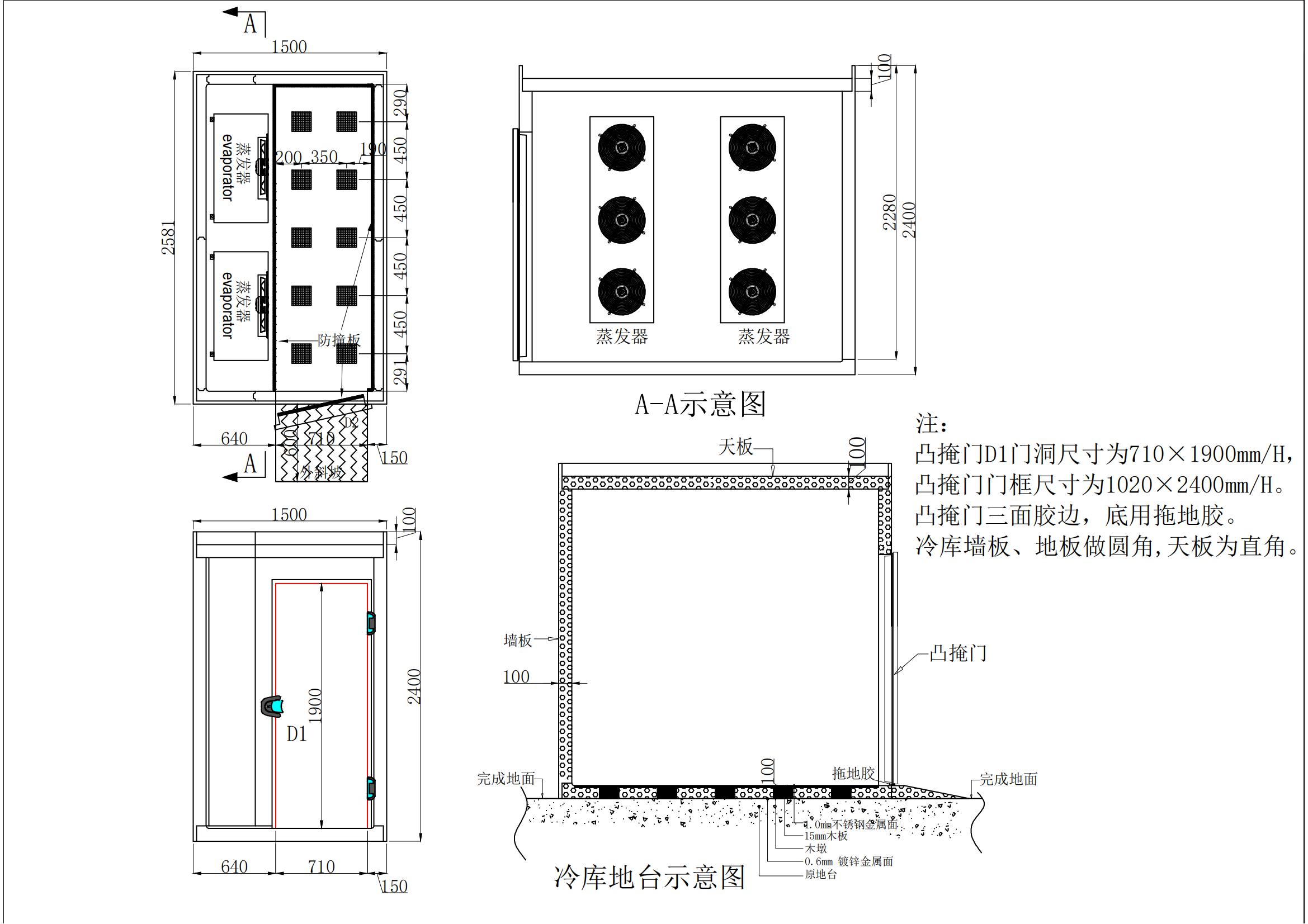

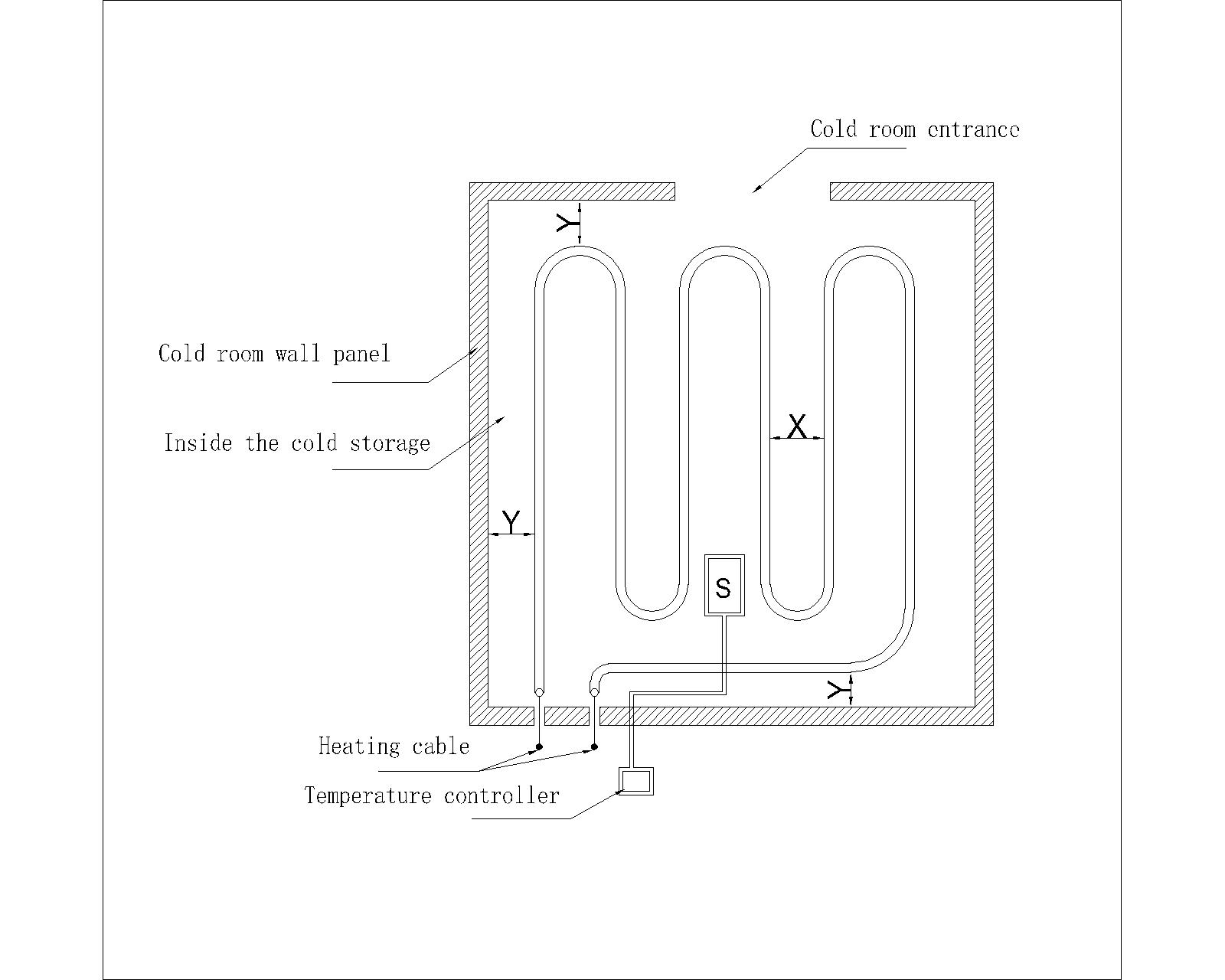

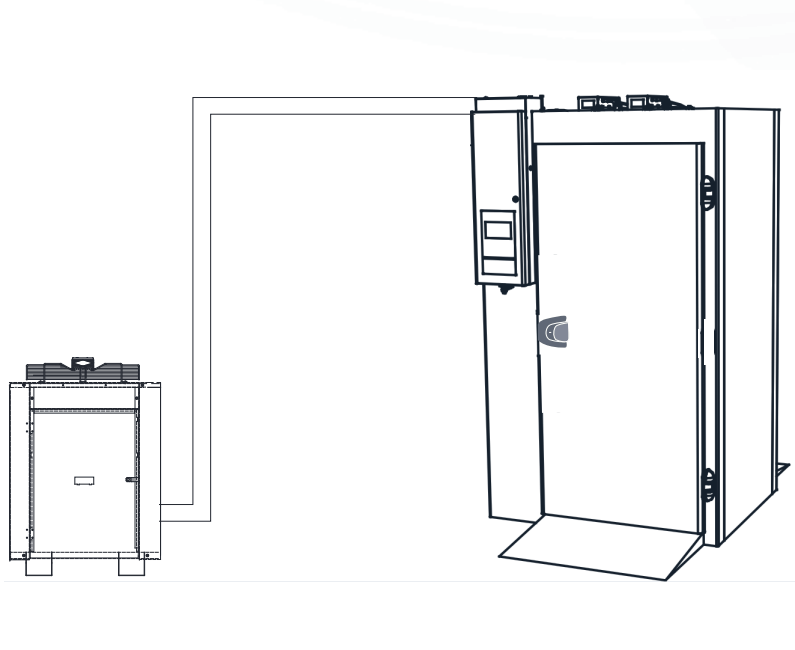

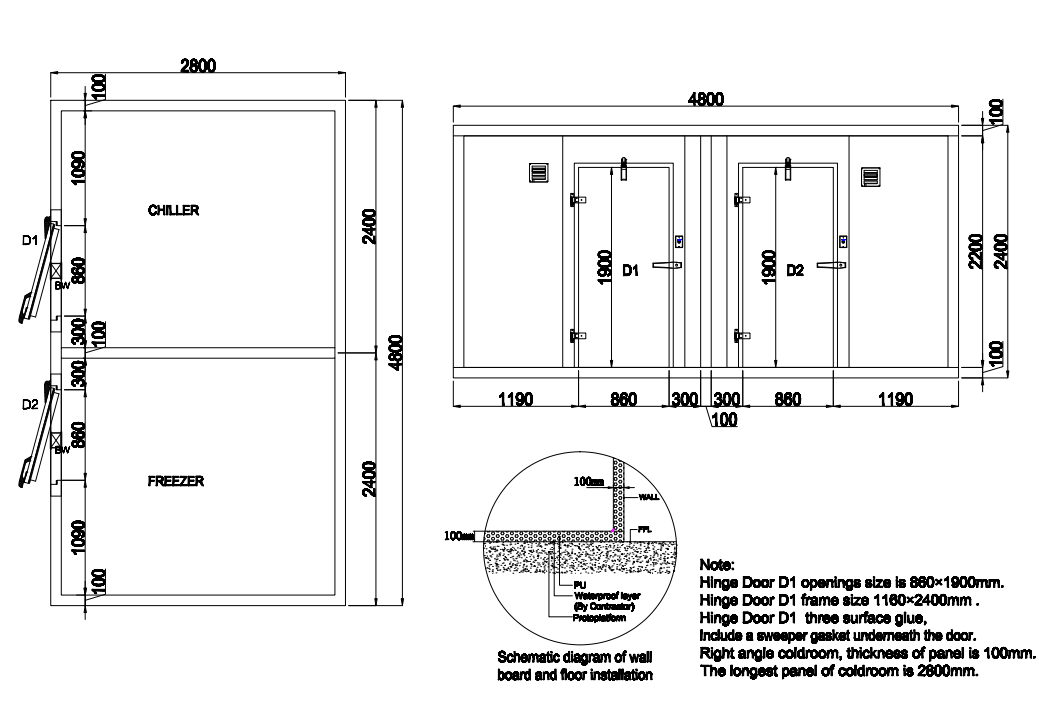

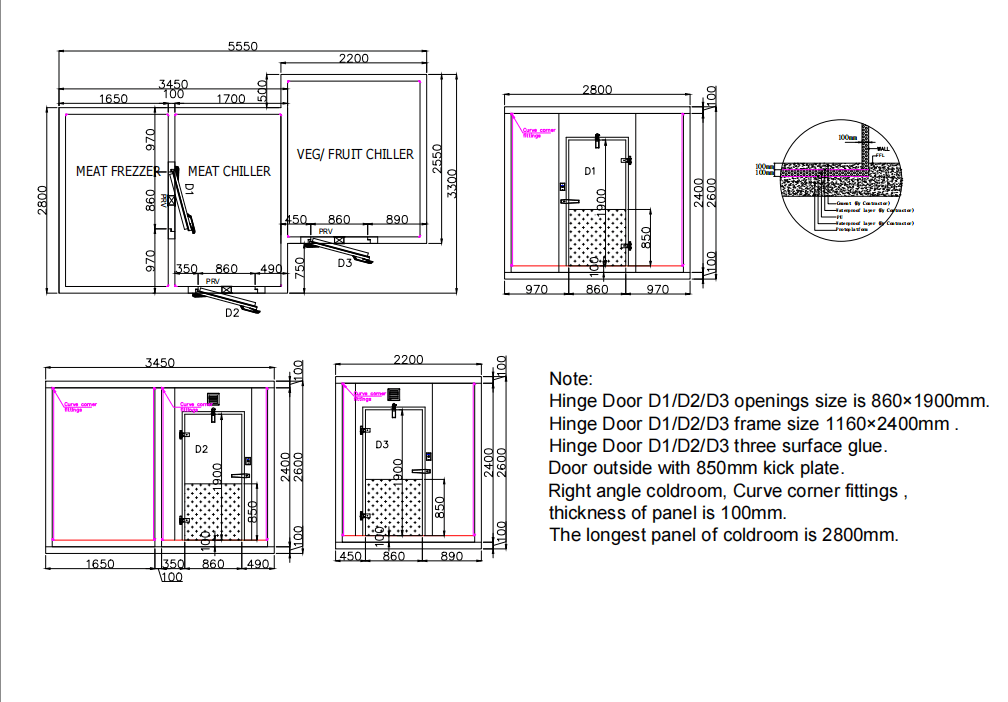

Cold storage design diagram, for reference only;

| Model | Size | High temperature cycle | Low temperature cycle | Refrigerating capacity | Power supply | Electricity | Tray | ||||

| Time | Weight | Temperature | Time | Weight | Temperature | ||||||

| OMBC1201 | 1500*1400*2400 | 90min | 120kg | +90℃/+3℃ | 240min | 90kg | +90℃/-18℃ | 9650W | 400V/3P/50Hz | 15.8A | 1Trollry gn2/1 |